Overwrapping

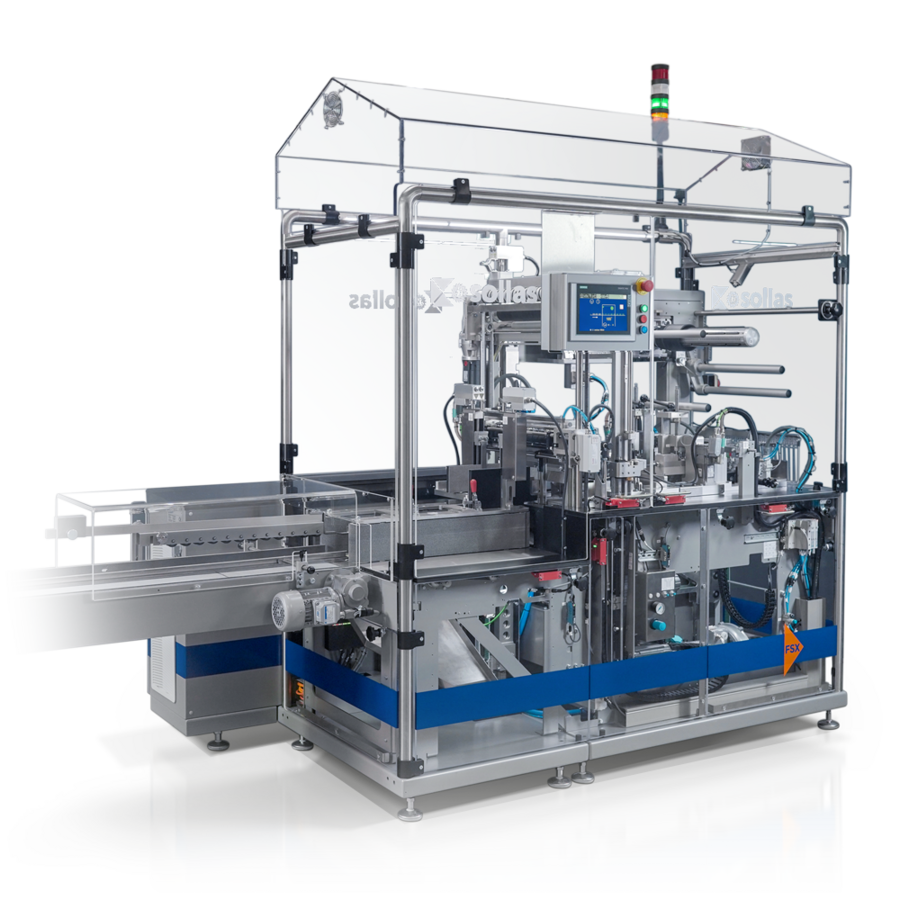

Sollas overwrapping machines fold packaging material elegantly around a rectangular or squared product (or stack of products), creating envelope-style folds on two sides. No bulges of packaging material will be visible on the product because the films is folded neatly and tight. Film, biodegradable film, or paper can be used for the packaging, and if desired we can ensure that preprinted materials are exactly positioned for excellent visibility on the product.

Overwrapping is often used on top of regular packaging to give products a luxurious look and/or to protect the product from scratches and other damage during transport. However, overwrapping can also be used as the only packaging, such as for stacked products like paper.

The main benefits of overwrappers are:

- Luxurious presentation

- Promotion possible on preprinted packaging material

- Closed packaging

- Optional tear tape for easy opening

- Flexible size range

- Easy of operation

- Energy-saving as no shrink tunnel is required

- Both plastic and paper can be used

Overwrapping machines

Copyright © 2023 SOLLAS HOLLAND B.V.