Support

Online

Read machines remotely and immediately troubleshoot problems.

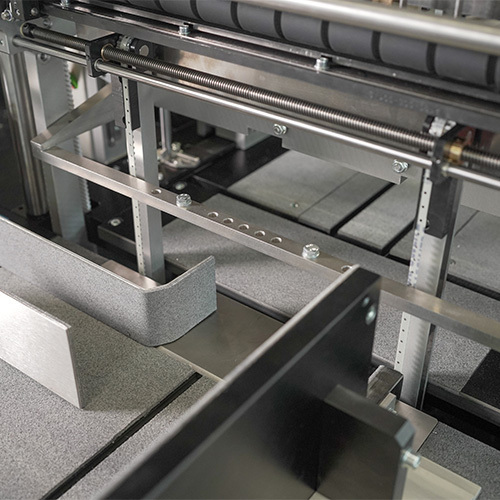

Fully servo-driven, flexible, and quick

The Sollas SXP is a fully servo-driven overwrapping machine that can wrap up to 80 products per minute. The machine is based on our Sollas SX series, but cam-driven movements are replaced by servo-driven movements. The SXP can package a wide range of products both as single products or as bundles. The change-over time between different products is minimal and the process can be fully automized.

The addition of OMAC PackML standards makes it easy to exchange information with other systems, making the SXP industry 4.0-ready.

Each movement is optimized to reduce the impact on products.

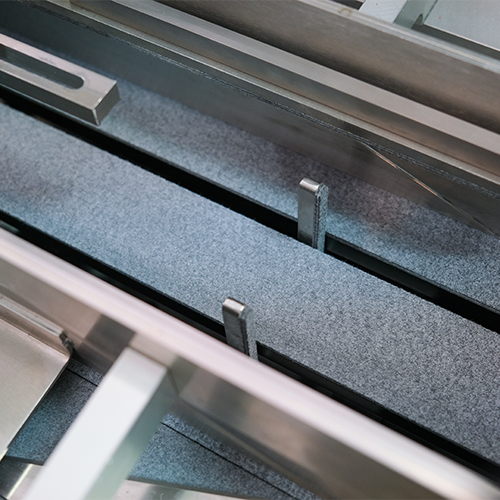

By transporting wrapping material over vacuum belts, it is possible to handle wrapping materials with varying thickness. It also increases wrapping speed and ensures correct positioning of the wrapping material.

To ensure the best folding and sealing quality, prevent products damaging each other, to reach a high speed and self-empty of the machine.

| Processes: | Polypropyleen, coated paper, recyclable BOPP en biodegradable BOPLA*** |

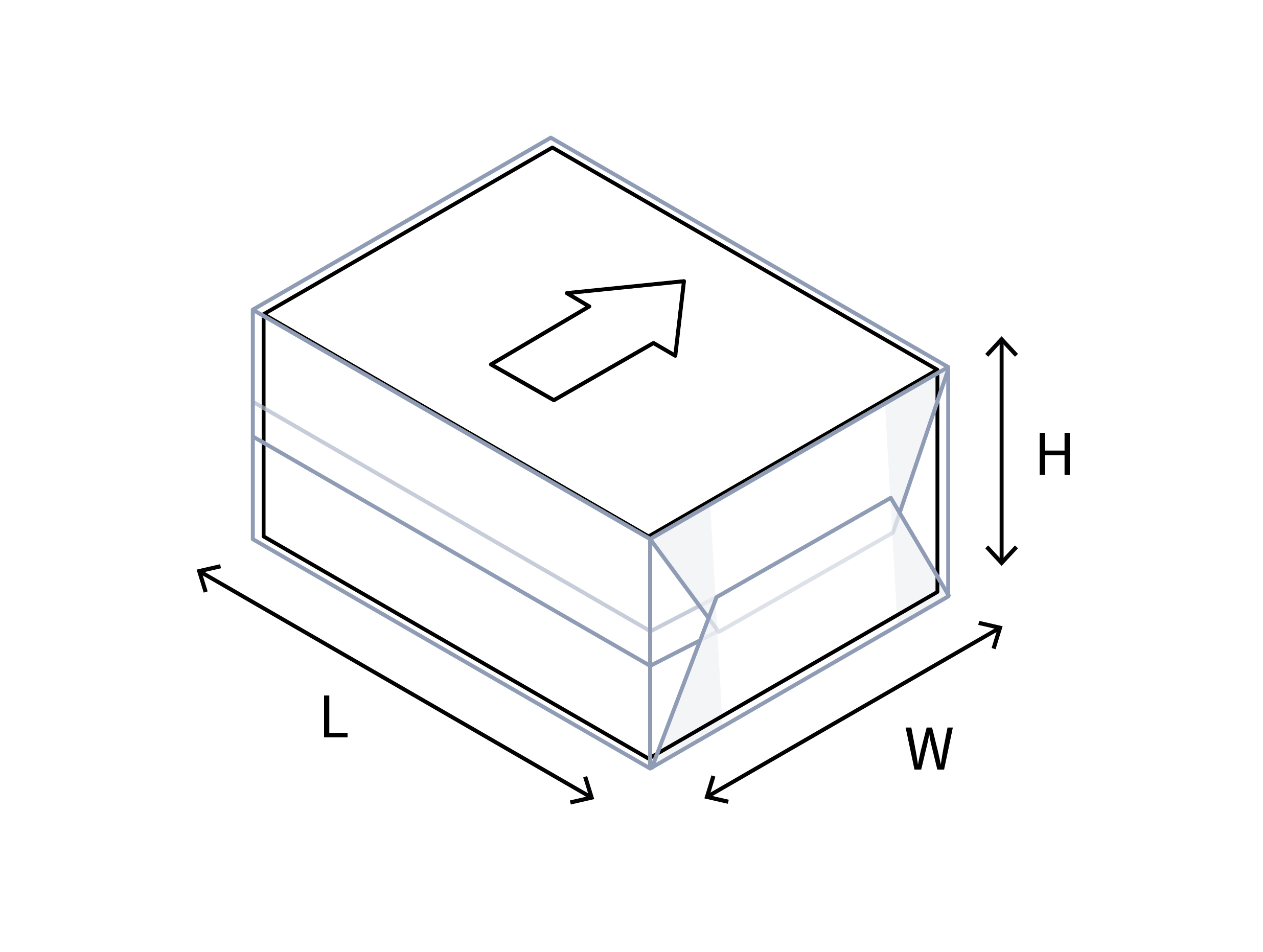

| minimum product size (mm): | L 40 W 40 (20)* H 25 (7)* |

| maximum product size (mm): | L 300 W 225 H 96 (125)* |

| Maximum output: | 60 / 80 ppm (conveyor)** |

| Film width min/max: | 50 - 435 mm |

| Film-roll diameter max: | 400mm |

* Numbers within brackets indication optional changes. ** Depending on product and packaging material. *** In general, all common heat-sealable packaging materials can be used. When in doubt, Sollas will gladly test any material that you which to use.

High quality packaging machines since 1948

Copyright © 2023 SOLLAS HOLLAND B.V.